The current economic climate has put cost reduction on the agenda of nearly every boardroom, and maintenance spend is under the microscope. However, poorly planned maintenance cost-cutting can ultimately lead to excessive costs, poor performance, or worse still, catastrophic equipment failures.

Maintenance costs are estimated to range between 15% and 40% of total production costs (Dunn, 1987; Lofsten, 2000), making it an obvious target for cost savings. However, a reduction in maintenance costs with no planning means a reduction in routine maintenance or an attempt to extend asset life. Done correctly any decisions to reduce or alter maintenance plans need to be made with a careful understanding of over-maintaining, under-maintaining, cost impacts of failure, and the underlying cost curves.

The asset management trilemma is risk, cost, and performance. It is critical to understand the interplay between these key metrics. If optimizing to minimize the risk profile, costs will be high and performance may be compromised due to frequent outages to maintain assets. Optimizing by performance may also lead to high maintenance costs and potentially a higher risk profile. If optimizing by maintenance costs, the risk of failure will be high and performance will likely be low due to regular unplanned corrective activities.

.png)

Hence the complex decision-making associated with setting optimal maintenance plans. What is the risk tolerance for the systems or assets? What are the performance requirements? What maintenance budget is available? A component-based reliability model enables effective decision-making through the evaluation of this interplay.

Understanding maintenance cost optimization

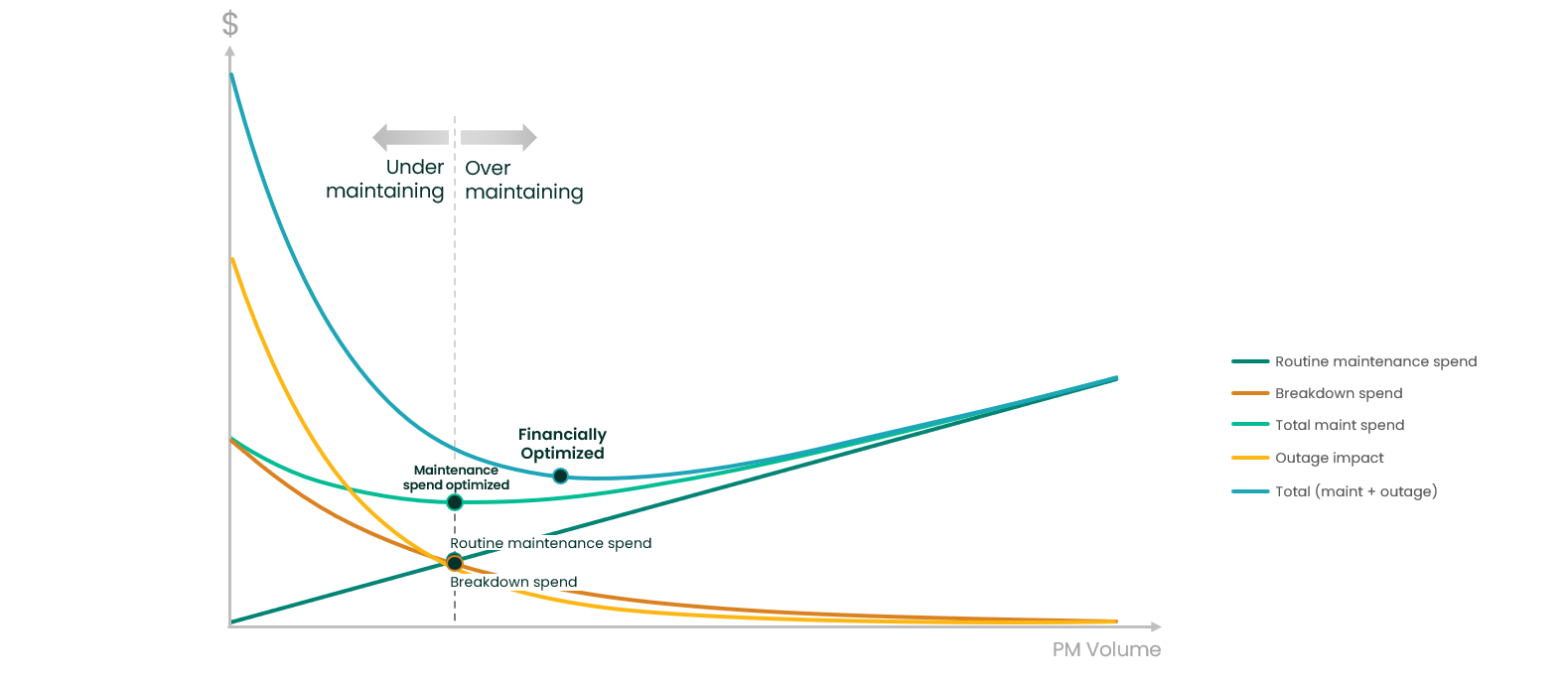

When optimizing by only maintenance cost, the goal becomes to minimize maintenance spend. It is a common misconception that the lowest maintenance spend option is a complete run-to-failure environment, whereby assets are left to fail in service and only corrective maintenance is performed, which fuels the theory that only the maintenance required is being completed. In reality of course, when many assets are left to fail in an unplanned manner, the corrective maintenance is far more costly than a corrective activity that might be required as a result of an asset inspection or condition assessment.

Take the simple case of a bearing failure. When left to fail in an unplanned manner, it is likely the whole component will require a change out due to housing damage and/or shaft damage, or at times catastrophic damage to the whole asset. In these cases, it is easy to see that with ongoing condition assessment, where the bearing degradation is picked up before failure and a change of the bearing alone is possible, the cost of the corrective activity is greatly reduced. Alternatively, we may be able to perform a fixed time change of the bearing and prevent the more costly unplanned corrective activity. The question of course is, which is the lowest cost option? Corrective maintenance on failure, periodic bearing condition assessments then a smaller corrective action when degradation is detected, or a fixed time change?

Naturally, there are many variables to consider when determining the optimum, however, it is important to note that a maintenance cost optimization strategy still includes a maintenance plan. The second important note is that the maintenance cost optimized point is the lowest point the maintenance cost can go. If you try to cut costs beyond this optimum, which can only be attempted through reducing routine maintenance, the costs will rise due to the more costly corrective actions that will be required. There is most definitely a minimum maintenance spend point for every asset, system, and plant.

Understanding total cost optimization

If we implement a maintenance cost optimization strategy, we will be operating a high-risk, poor-performing system. The alternative is to generate a total cost optimization strategy. In these cases, we factor in not only the cost of maintenance but the additional cost of lost production and other risk associated with asset failure. In many industries, the lost production costs alone dwarf maintenance costs and so these optimizations generally drive us to conduct more routine maintenance to prevent or predict failure.

A total cost optimization then leads us to a high level of routine maintenance, when compared to a maintenance cost optimization, and thus a high maintenance spend.

Right-sizing maintenance spend

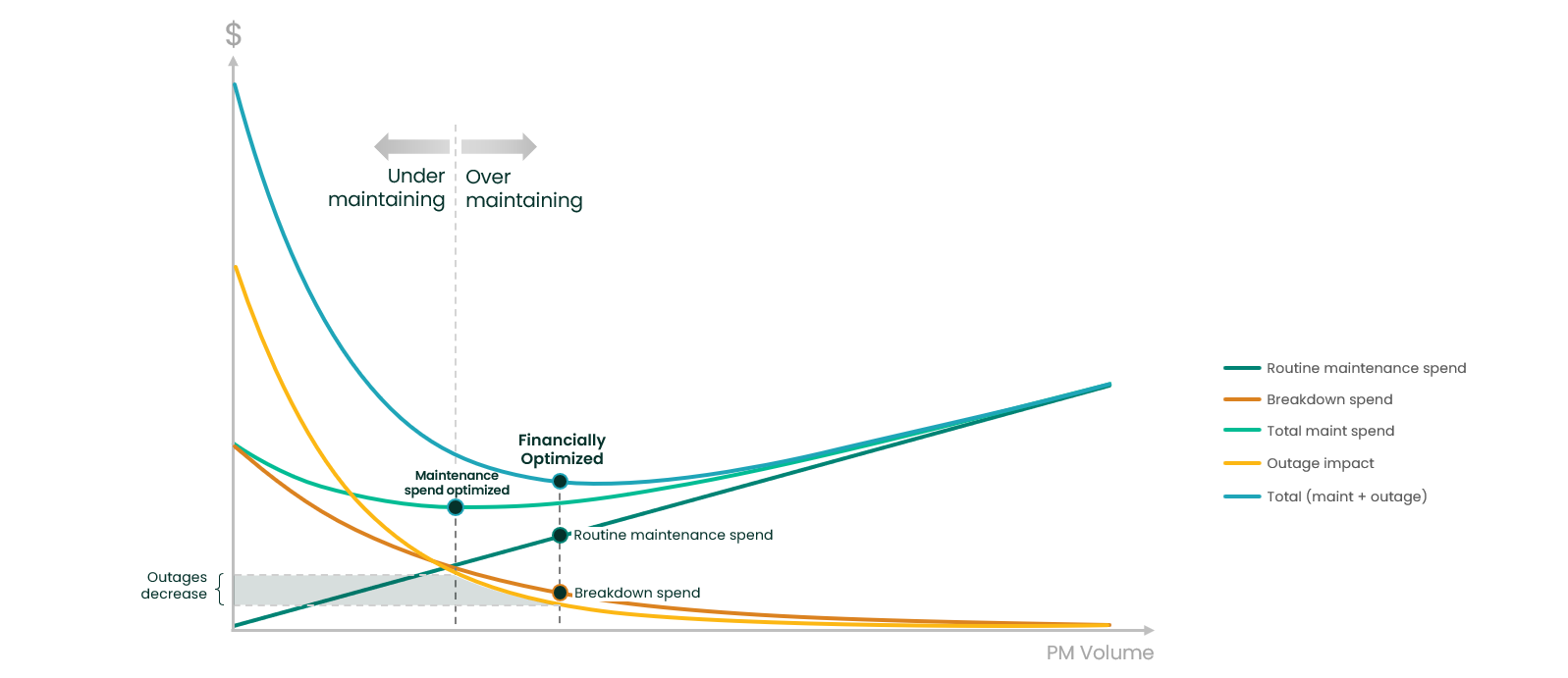

In reality, the right level of maintenance spend and associated routine maintenance will lay somewhere between the maintenance cost-optimized strategy and the total cost-optimized strategy. This is predominantly because organizations will have different risk appetites dependent on the type of risk. Risk is also just that, a risk and not a certainty, leading us to manage within a risk profile set by the organization.

When evaluating the maintenance strategy and plan, no one wants to intentionally under or over-maintain their assets. This drives constant pressure to cut maintenance spend, where organizations will often look to reduce routine maintenance. Tasks once performed weekly or every six months are set to be completed fortnightly or every year.

Decisions about which tasks to eliminate or reschedule are often subjective, made by those close to the asset but with an absence of structure or data. It is difficult to track the impact these decisions may have down the line because there was no substantiation of the decision-making or subsequent recording of it. Therefore, a reduction in routine maintenance can often lead to failure and shorten asset life. Consequently, any savings the organization hoped to realize, are heavily outweighed by costs associated with unplanned downtime, lost production, or even additional corrective maintenance required after a catastrophic failure. In some cases, these costs can be 10x or more than the initial maintenance spend on the failed asset.

So how can you lower the cost of maintenance without introducing additional risk?

For starters, you need a complete understanding of asset risk and associated costs. You also need a structured, reliability-based, decision-making process that helps you weigh up the cost of maintenance vs. the cost of risk, and determine a maintenance plan that balances both.

An Asset Strategy Management platform can offer models to help you calculate the cost of maintenance and the cost of risk to find that optimal balance. With these models, you can identify short-term savings that won’t end up costing you more in the long term. These models create the foundation for constant alignment of maintenance strategies and resulting maintenance spend based on the current operating context and risk appetite.