Every year, millions of dollars needlessly go down the drain in large organizations. It’s money that can easily be saved, if you know why it’s disappearing and how to save it.

To illustrate, let’s look at a real-life example.

We are regularly asked to lead projects to review maintenance strategies sites and assets that are not meeting their availability targets, are suffering frequent unplanned failures, or high costs.

We typically set to work collecting the asset hierarchy, work order history and current maintenance plans. Using all this data, we apply sophisticated methodologies to build an optimised maintenance strategy. In a particular project the resulting revised strategies were forecast to reduce maintenance costs by -18% per annum, and improve availability by +3%.

It was a great outcome. But – and herein lies the problem – the site failed to effectively implement and execute the strategy, and so continued to suffer from unplanned failures and poor availability. There’s the money down the drain.

To truly realise the value good strategy needs to be implemented and then updated over time. In essence the strategy needs to be managed. This includes workflows, review and approval by appropriate subject matter experts, use of generic content wherever possible and data driven decision making.

Learning from past failures

Ten years ago, when Reliability Centred Maintenance (RCM) was really hitting its strides, more and more organisations started investing in the task of developing maintenance strategies. But according to research a massive 60 per cent of these strategies were never implemented. Think of the money wasted.

Or, if a strategy was implemented, it is likely that it may get changed over time with little or no oversight, typically the good strategy work is undone for it only to be put back to how it was.

Realistically any change to a strategy such as the interval, durations, specific tasks, and instruction content should be managed with a dedicated workflow which would include justification and the opportunity to utilize any great improvements across your entire asset base.

The power of combining Work Management with Strategy Management

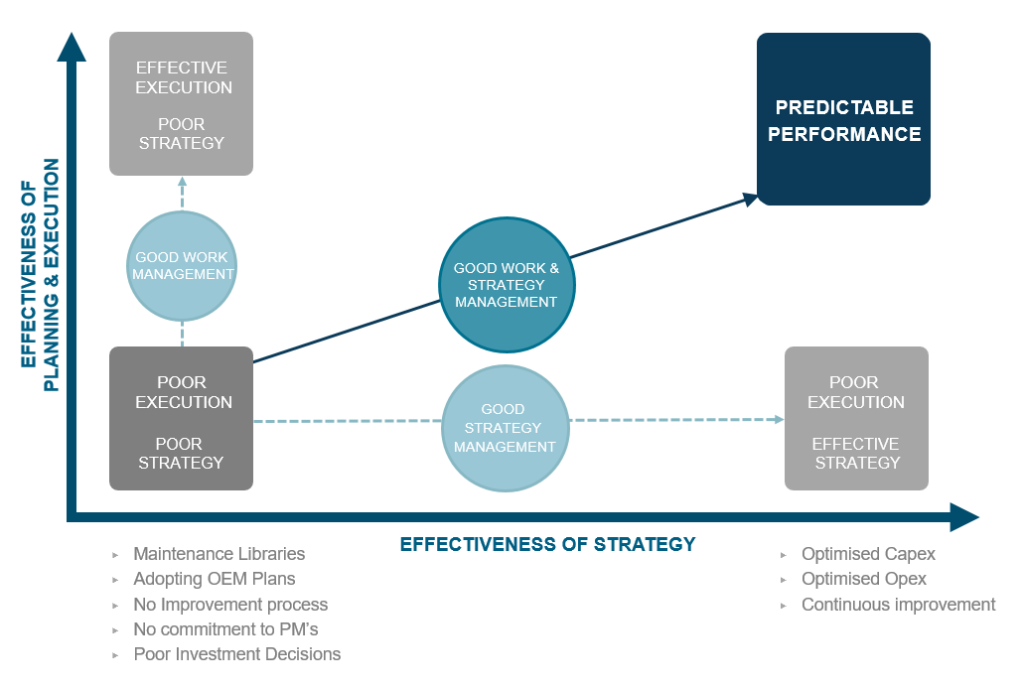

To fix these endemic problems, the focus of an organization needs to evolve to strategy management as well as work management.

Think about it. Work management is all about executing tasks. Strategy management is all about deciding what tasks should be executed. You can have the best work execution process, but if you’re not working on the right strategies then it won’t deliver results. Asset Managers need to make sure that teams are effectively executing the right strategy.

Furthermore, reliability and maintenance teams need the agility to adapt if a positive change is made to a strategy at one site in a multi-site organization, or a common asset used multiple times on a single site. How do you quickly deploy this cost-saving change across other sites in the organization?

For example, think of a water utility that operates 400 pump stations across the country, with each one operating the same equipment. Say there’s a pump failure at one site, and a technician does some good root cause analysis work which leads to a recommended strategy around a task that needs to be done. If their decision could come back to a central area for review and approval, and then get deployed efficiently and electronically to all the other pump stations, the utility could potentially save thousands on future fixes, reduce risk and improve performance.

Wherever you find pockets of excellence you need to deploy them everywhere, effectively.

Adopt a best practice approach and create a culture of excellence

The secret of successful strategy management lies in looking beyond the SAPs and Maximos of the world. You can try to standardize these systems for a “generate once, use many times” approach, but it won’t work. A CMMS is designed to manage work tasks, not manage strategy.

Instead, you need a separate approach and solution for strategy management, which directly integrates with your work management system. This way, if your reliability team and subject matter experts devise a new asset strategy that is going to save your organization millions of dollars, then you can be assured that it will successfully be applied to all the relevant assets across all sites. Likewise, you will gain visibility into single-site strategy excellence and be able to quickly and easily deploy it enterprise-wide. With an Asset Strategy Management program, your asset strategies will be dynamic, constantly evolving and will instill a culture towards achieving excellence in reliability.

This makes reliability a reality.