A next-gen power company used Reliability Centered Maintenance to deliver a projected savings of $130 million over 20 years and dramatically reduce the effects of failures. They now have a plan for the long-term utilization of RCM for other assets.

As we march further into the 21st century, the power sector is undergoing a massive shift. With climate change high on the global agenda, the industry as a whole is committed to finding alternatives to conventional fossil fuel power generation. Low-carbon power sources like wind, solar and hydro are being pursued by even the most traditional power companies.

To meet this commitment to produce a certain amount of power from renewable energies, these companies are investing significant amounts of money in new technologies and new assets. And with this comes a raft of other costs that are impacting on the bottom line - with maintenance one of the big ones.

This was the case for our client, a global power generation, and distribution company. Following the acquisition of a fleet of new wind turbines, it rightly predicted that maintenance costs could skyrocket if it wasn't careful. So the power company brought in ARMS Reliability to conduct a Reliability Centred Maintenance (RCM) study - to plot the best maintenance path for the turbines into the future.

The Problem

Having recently committed to generating 25% of its total power using renewables, the power company invested $450 - $500 million in purchasing 141 wind turbines and sited them in an ideal, windswept location. Each turbine would be capable of producing 2.3MW with a typical efficiency of 30%; and the entire wind farm would contribute 8% of the total power generation for the company, which at its most efficient is 450MW.

On paper, it looked like a great investment, yet the company was concerned that maintenance - as yet an unknown entity for this new technology - would prove a costly blow.

For example, in the event that significant repairs were required to one of the massive wind turbines, the crane needed to maneuver the turbine would be very hard to come by. It could take months for a crane to become available, and the costs for transport and hourly hire were huge. What was the risk of a crane not being available? Were they better off buying one outright, sharing the cost with neighboring companies, or shouldering the occasional, yet very expensive hire cost?

This is a typical scenario and just one of the many factors that need to be considered when new technologies like wind turbines are introduced into existing operations.

The Solution

Any new technology brings with it a raft of unknowns when it comes to operations and maintenance. Even with strong support from the OEM and the provision of thorough training for the operations team, it is still hard to quantify costs and, more importantly, identify ways to save on maintenance in the early stage.

ARMS Reliability was brought in to demystify these unknowns. The strategy? RCM.

RCM involves the early mapping of maintenance plans using proven reliability engineering techniques. It plots a clear path for maintenance of new assets and provides management with reassurance around ongoing costs.

An RCM study determines the optimal maintenance strategy for the new assets, and predicts the maintenance budget and spares usage over a 20-odd year lifetime. It also models different maintenance strategy scenarios to compare risks and improvements over this lifetime, to enable the better long-term management of the assets.

For their wind turbine project, failure data was first gathered from a variety of sources - such as work order history, spares usage rates and interviews with the personnel responsible for maintaining the equipment. Given that this power company hadn't been using wind turbines for long, the failure data wasn't all that comprehensive - yet it wasn't seen as a stumbling block.

Using this data, along with OEM maintenance manuals and spares catalogs, a preliminary RCM model was built - with the intention of fleshing out the model during facilitations with staff. During this process, technicians and engineers had direct input into the maintenance activities that were included - to create a sense of ongoing ownership of the maintenance strategy.

From the facilitation process, the RCM model was validated and then optimized by assessing each failure mode by the cost, safety, environmental and operational contributions to reduce cost and risk. They identified that maintenance of the main gearbox used to power the wind turbine was problematic - with main gearboxes costing $300,000 and the aforementioned cranes adding significantly to the repair cost. It's here that further reliability engineering techniques - like Root Cause Analysis - were used to make further improvements to the maintenance strategy.

The Outcome

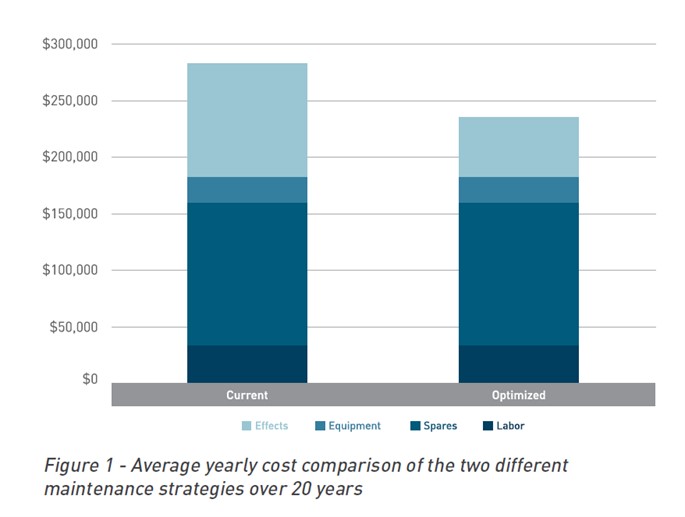

As the graphs show, an RCM study delivers long-lasting benefits for this company- or, indeed any organization that has invested in significant new technologies. The savings are achieved through a reduction in unplanned downtime, the avoidance of production losses, and a fall in risk-based costs.

Futhermore, an RCM study will reveal any gaps in the existing maintenance strategy, or conversely deliver peace of mind that existing strategies are working.

Figure 1 shows the outcome of the RCM report for the power company. The first column shows what their existing strategy will cost per year; while the second shows the optimized model. This latter delivers $46,000 savings per turbine per year, or close to $130 million over 20 years across the fleet.

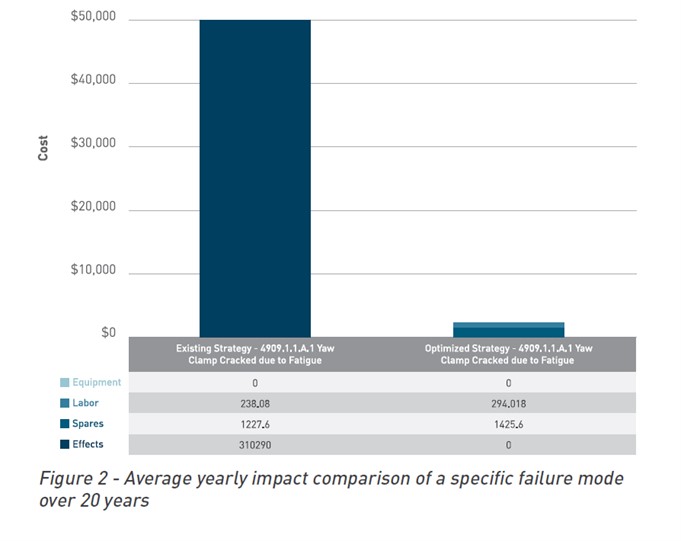

Figure 2 shows the actual impacts of a specific failure mode - where the optimized strategy has dramatically reduced the effects and costs associated with this failure mode.

Using the right technologies and facilitators, an RCM study has broader benefits for operations and maintenance teams. It can boost overall capacities by providing training and development; and integrating RCM software tools with other proceses for continuous improvement. These tools can be used for long-term forecasting of entire fleets of assets, and to empower companies to be on the front foot when it comes to contract negotiations with OEMs for maintenance.

As the potential savings for this company demonstrate, an RCM study is a powerful technique to optimize a maintenance strategy for any new or existing asset, and delivers real savings into the long term.

Questions? We’ll put you on the right path.

Ask about our Reliability Centered Maintenance services and technical solutions. We are ready to help.

Contact Us