A RAM analysis is a proven approach and effective tool for assessing system reliability, availability and maintainability. It is crucial to support the through-life viability of a project. The aim of a RAM analysis is to identify any significant causes of loss of operational availability or issues that may limit the production throughput and then propose improvements to the design or maintenance program to enable RAM targets and project requirements to be met.

ARMS Reliability utilizes a variety of RAM analysis tools for each project phase to enable asset management plans to be created in a streamlined way and to be consistent with the operational objectives of the project.

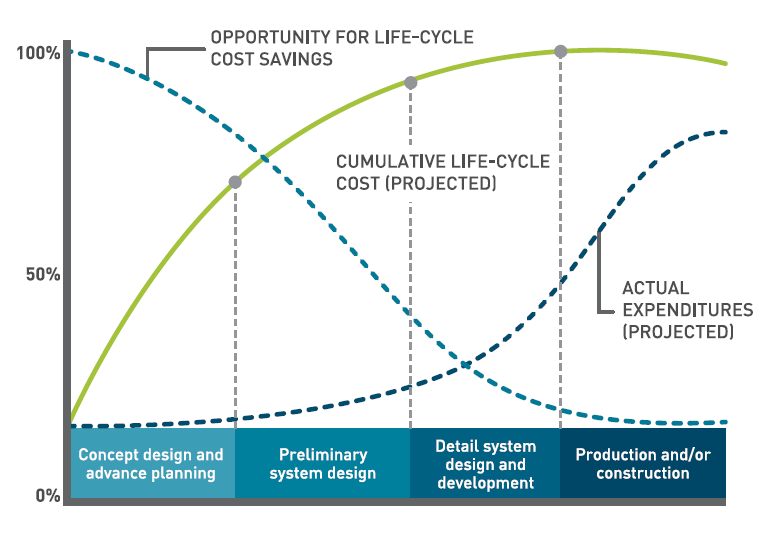

Ideally, a RAM analysis, supported by a Failure Mode, Effects and Criticality Analysis (FMECA), would be conducted in the design stages of a project. As design moves through the various FEED stages from concept, pre-feasibility, feasibility, detailed design, commissioning and handover, the RAM model also matures from high-level assumptions to specific failure mode models.

How ARMS Reliability Helps

Validate design and reliability requirements

By identifying critical reliability issues early in the design, you avoid making expensive changes after detailed design, procurement, construction and commissioning.

A reliability block diagram (RBD) is a diagrammatic method to show how equipment interconnects in a logical manner to show the failure logic of a system. Interdependencies between equipment, spares, resources, other equipment and events are clearly represented and enables you to simulate the likely behaviour of a system.

Bottlenecks can be identified, and equipment importance ranking provides focus to critical areas where design parameters such as redundancy, intermediate storage and equipment sizing can be reviewed, and various alternatives evaluated to give the best predicted outcome.

Document and store reliability assumptions

As the design matures from concept to detailed design, reliability assumptions keep pace with procurement decisions, maintenance reviews, operator input, commissioning performance. Data records are kept for operational teams to update models, understand strategy requirements and build out detailed plans and work instructions.

Quickly find the underlying assumptions for equipment reliability, likely failure rates, failure modes, production capacity, redundancy, spares availability and maintenance outages.

Enabled maintenance decisions

Make every decision with confidence on what maintenance to perform, whether it is off line or online, spares required, refurbishment effectiveness, and warning signs and time required to respond. These are all important in the determination of the capacity of the system to deliver, to be available and to avoid interruptions between planned outages.

Critical sparing for maintenance

Forecast accurate spare holding levels for planned work to ensure an economical balance between procurement and holding costs. For unplanned work and breakdowns, ensure holding levels are optimized against the holding cost and cost of an outage. Model the spares supply chain and factor in logistical delays and usage rate that may impact availability and ultimately system downtime.

Determine availability and capacity

Understanding the availability of a plant and its capacity to produce enables decision making throughout the FEED process and when designing new projects. There are many options to be considered, including equipment sizing, multiple parallel streams, intermediate stockpiles and buffers, catch up capacity, work-arounds, standby arrangements.

By modelling all the variables, such as power supply, steam and utilities, relief systems, material transport, load in stations, load out stations, cleaning processes, regeneration requirements, and statutory regulations for inspection, you will be able to validate the system capacity and identify bottlenecks and critical areas.

Detailed system model

As the project phase matures to detailed design, a detailed system model ensures all elements of the design are aligned to the project objective: procurement, equipment vendors, maintenance strategy and plan definition, redundancy, type of equipment, infrastructure, instrumentation and protection systems, resourcing.

The detailed system model provides the basis for defining master data, establishing detailed maintenance plans, work instructions, Bills of Material, Spares levels. In many projects, these steps are duplicated by the O&M team, often without alignment to the project objectives. Use of the Systems model streamlines ramp up, reduces the commissioning phase and provides the base for managing further improvements, without reinventing the wheel.

Loading maintenance plans to EAM

Developing maintenance strategies, plans and work instructions produces thousands of documents. Implement work processes to define the master data standard and ensure all uploads meet the standard before uploading. Standardize tasks across the enterprise for same work on the same equipment or similar equipment.