THE PROBLEM

A refining facility, designed to selectively remove and refine valuable metals, was shut down following only 18 months online. A run-to-failure facility maintenance strategy and underutilized computer maintenance management system [CMMS] – together with a “maintain production at all costs” mandate – resulted in:

- Catastrophic equipment failure

- Damage due to undesirable and unsafe maintenance practices

- Negative environmental impact

- Ultimately, plant bankruptcy

A new in-house management team was created and an engineering procurement construction management [EPCM] company was brought in to address the main engineering challenges. A feasibility study was conducted, and a holistic review of the management systems was performed; a key item identified for overhaul and upgrade was the CMMS.

ARMS Reliability was brought in to assess issues with the site’s current maintenance strategy and systems to fully understand the current situation.

THE SOLUTION

We discovered that the plant’s CMMS setup was severely limited and unable to deliver useful information. For example, it lacked a consistent naming convention – ‘assets’ were frequently referred to as ‘systems’ and vice versa, some assets were listed multiple times, the hierarchy was unstructured so that assets and systems existed at the same level, and there was an excessive dependence on ‘default equipment’ as a category.

Additionally, the site’s assets and equipment had no BOMs, so there was no real-world information available to inform stores, warehouse inventories, or spares strategy.

These gaps fostered an unsustainable culture within the facility’s maintenance department. Maintenance staff were continually ‘firefighting,’ fixing the symptoms rather the causes, and hoarding spares. The previous management’s lack of understanding around reliability, meant there was no planned maintenance, no maintenance history, and no key equipment performance metrics. As a result, the maintenance staff weren’t doing planned or precision maintenance work, had been driven to perform undesirable maintenance practices just to keep the refinery running, and had limited opportunity to prevent ‘flare-ups’ and breakdowns from continuing to happen.

Clearly, the plant’s maintenance systems needed a solid foundation to be established. ARMS Reliability defined the steps for overhauling, upgrading, and providing data for the CMMS:

|

|

|

|

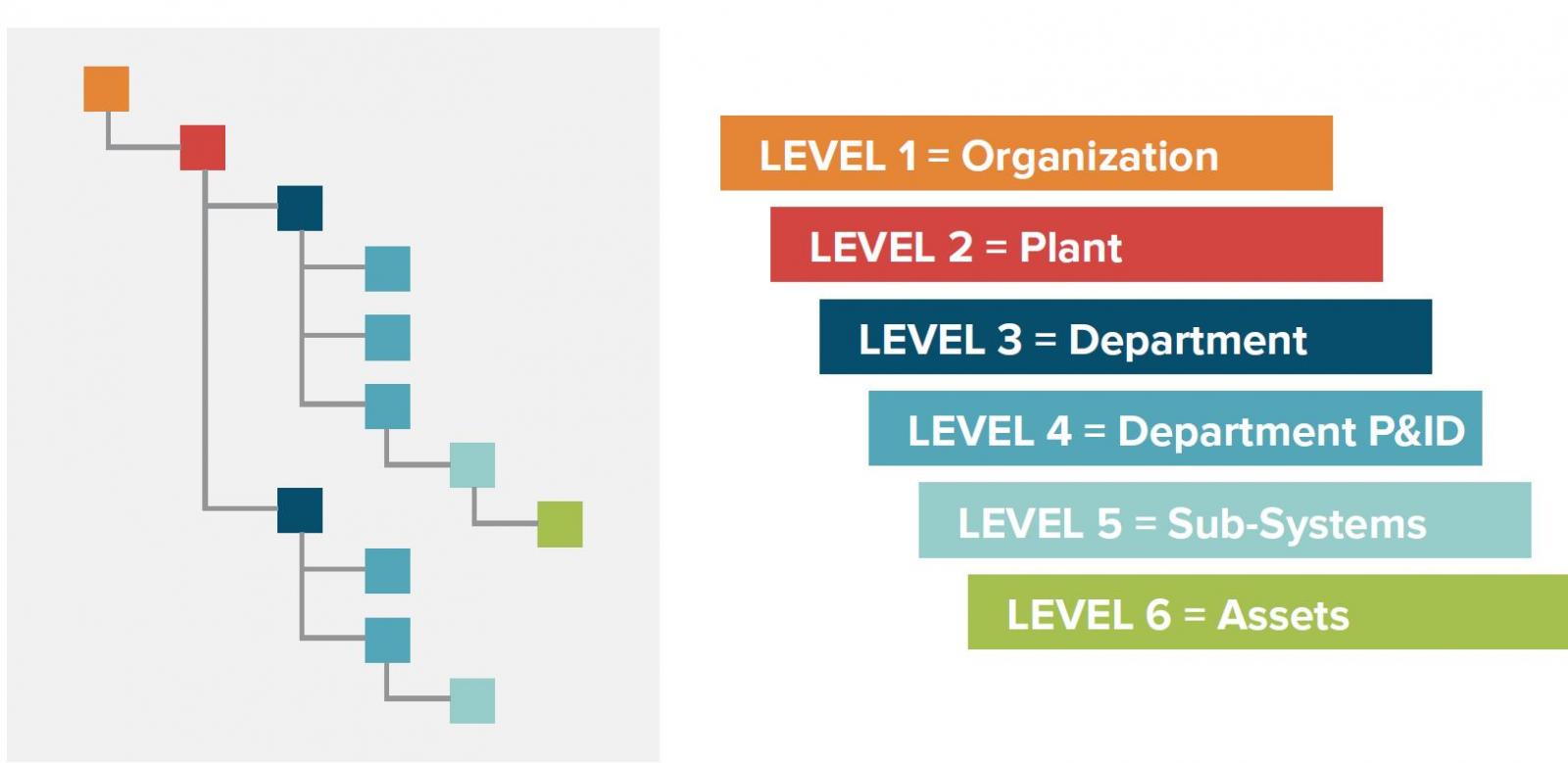

Location Hierarchy Completely rebuild the hierarchy to reflect systems for all installed assets. |

Criticality Analysis and BOM Understand the critical assets and their components and create a Bill of Materials for critical assets. |

Maintenance Strategy Develop a justified, risk-based strategy for all installed assets. |

Location Hierarchy

We assessed the client’s needs, then reviewed all of the site’s pipe and instrumentation diagrams [P&IDs], and implemented a standardized location hierarchy and asset-naming structure:

Once the new maintenance hierarchy was completed, the disparity was clear: The previous hierarchy had 3,508 total line items, including locations, systems, and assets; the new hierarchy has 6,505 assets alone.

Criticality Analysis and BOM

We conducted workshops with the refinery’s maintenance and operations teams to determine the criticality of all assets. Together, we agreed that based on the criticality of the assets we would follow different strategy development processes with effort aligned to criticality.

Additionally, we developed BOMs for all extreme- and high-criticality assets, which will provide the necessary information to manage and maintain the materials for the facility.

Maintenance Strategy

Most importantly, we provided a fully developed maintenance system for the site prior to restarting operations – including system-generated work orders for engineering, maintenance, operations, and reliability.

We began with original equipment manufacturer

[OEM] and equipment-type industry tasks based on equipment knowledge and experience at other plants; then, depending upon criticality, we assigned optimized models, task-based models, or adopted a risk-justified run-to-failure strategy. Tasks were assessed and then packaged into executable routes, and we then provided all information in the required format for seamless CMMS implementation.

We also assisted with reworking the facility’s organizational structure for optimal effectiveness and supplied key performance indicators for maintenance both during implementation and in sustaining phases.

THE BENEFITS

Comprehensive

ARMS Reliability’s work provided our client with a fully developed maintenance strategy implemented into the CMMS. This optimized strategy has allowed the plant to prepare to re-launch operations with a detailed, accurate system designed to proactively prevent performance failure. Our team-based approach engages site staff in the development and implementation process, promoting understanding and buy-in, and ensuring the continued success of the new maintenance strategy.

Efficient

Our OnePM® software platform facilitated all phases of the maintenance strategy development and proved especially valuable during the implementation of the strategy in to the CMMS. OnePM® dramatically increased the speed at which the new maintenance hierarchy could be developed and new strategies deployed throughout the plant, to all 6,500+ assets; the implementation was completed with an estimated time-savings of around 80% over other methods that don’t have the scalability of OnePM®. Additionally, using OnePM®, the company could leverage the data gathered at this plant to improve performance at other similar facilities.

Sustainable

Using the newly developed maintenance strategy with the CMMS, our client can now deliver and sustain performance at their refinery – and do so with a new understanding of how effective maintenance strategies support and enhance the sustainability of the company as a whole. ARMS Reliability will continue its partnership with this client to continue to improve performance; long-term objectives include further refinement of maintenance metrics, introduction of a defect elimination process, and movement toward more predictive technologies.

Discover OnePM

OnePM supports the process of Asset Strategy Management to deliver the optimal balance of cost, risk, and performance.

Learn how