Almost every reliability leader we talk to is under immense pressure, and it makes sense: the lack of process and framework in this field means that most are set up to fail.

Specifically, we see reliability leaders heavily reliant on-site experts and reactive to transactional asset management, rather than having a shared strategy and data to optimize asset performance across all sites.

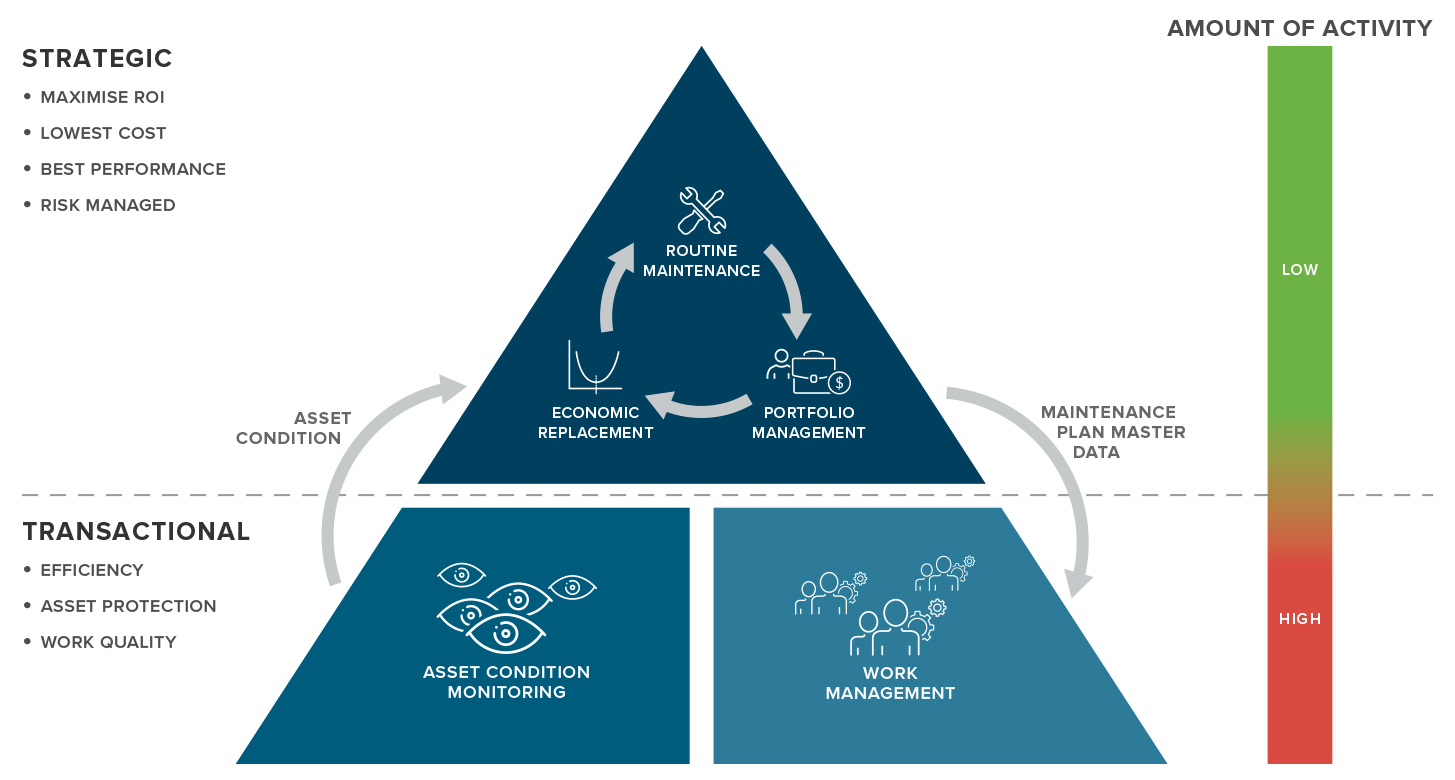

“Transactional asset management” includes the following activities:

- Asset health and condition monitoring

- Routine maintenance

- Asset repair and replacement, including emergency work orders

These activities are essential but largely reactive. A valve breaks, an alarm is triggered, and a work order is issued to repair or replace it. Three to six months later, the same thing happens again, and the organization is stuck in a pattern of break-fix where there’s no real change in the performance of that asset.

Some think that better monitoring is the answer, however monitoring in isolation can still lead to a reactive environment whereby the failure may be avoided but the intervention and downtime is still required.

The only way to resolve this or prevent it from happening in the first place is to put a strategy in place that helps you to not only manage your assets but optimize their performance. This strategic activity is what we call Asset Strategy Management (ASM).

ASM is a best practice approach to managing your asset strategies, organization wide. It is a process that connects physical assets and independent plants and sites to a central system and ultimately allows you to develop, implement, maintain and optimize asset strategies on an ongoing basis.

So instead of focusing all of your resources on reacting to the failure or degradation of assets, you can develop strategies and work management plans to drive the results you want. This might be better performance, lower costs, reduced risk or a mix of all three.

A two-sided approach to asset management

In the past, we used to think about all of the above activities falling into three separate but overlapping categories: ASM, Asset Performance Management (APM) and Work Management.

What we see emerging now though, is a better model which groups all the strategic or ‘above the line’ activities into one category and the transactional or ‘below the line’ activities into another. This two-sided approach is partially enabled by traditional work management solutions being expanded to include asset monitoring and other APM capabilities.

While it is unclear what direct impact this will have on APM, we do think it is important to be aware of this shift. We also recommend that people start thinking about asset management in terms of strategic and transactional activities and that they have the right systems in place to manage both.

You can download the Complete Guide to Asset Strategy Management for more information, including tips to ensure your reliability program initiatives live up to their true potential.