When it comes to asset management, many organizations continue to be hampered by high costs, a high volume of unplanned failures and, ultimately, an unacceptable level of risk.

The reason? There’s a piece missing in their asset management puzzle.

That piece is called Asset Strategy Management (ASM). It’s a simple – but vital – component of any asset management or reliability improvement initiative.

There are three questions you can ask of your organization to see if ASM would be of benefit:

- Do you know if you are currently executing all the strategies in your EAM system and at the set interval? (And, if not, do you know what level of risk you’re exposed to?)

- Do the strategies in your EAM system align to your agreed strategies or best-in-class strategies – on all assets? (And, if not, do you know what level of risk you’re exposed to?)

- Does your maintenance plan cover all the basic equipment care fundamentals and statutory or regulatory requirements – on all assets?

Answering ‘no’ to one or more of these questions sends a clear signal that you would gain immediate value from implementing ASM.

Delivering high reliability

Once an asset has been selected and installed, its ongoing reliability is determined by two things: how it is operated and how it is maintained.

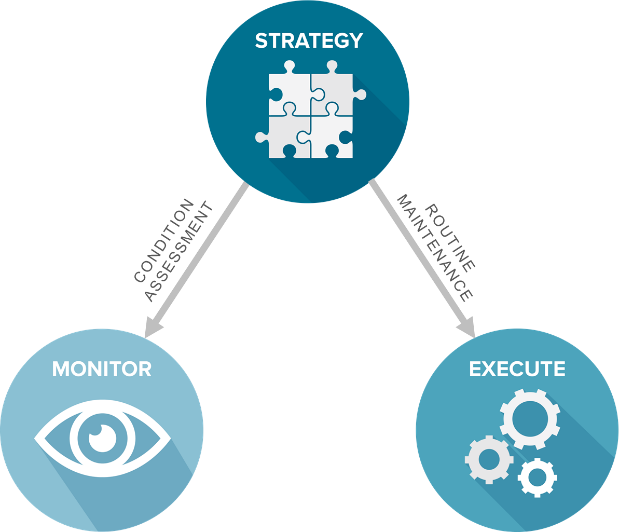

Putting operations aside for a moment, how you maintain an asset will directly impact its performance. And to decide how and when that maintenance is conducted, you need a strategy. Hence, an asset’s performance all starts with a maintenance strategy. At the most basic level, there aren’t many options for setting a strategy. You can either decide to execute a task at a regular interval to prevent or predict a failure; or you can monitor the asset for specific failure mechanisms, with an alarm or alert triggered if remedial action is needed.

It sounds easy enough. Yet many organizations will set a strategy in the first instance – upon installation of the asset – and leave it at that. There’s no ongoing management of that strategy. The implication of this is that, over time, the strategy may no longer be appropriate for how the asset’s being used. Or, someone may change the strategy without proper review or justification. Think about it. If someone goes into the EAM system and changes an interval of one of your maintenance plans without any review – and it turns out to be an inappropriate change – imagine the risk to your business.

Since strategy is the single biggest driver of asset performance, it must be managed effectively to ensure it remains optimal for the life of the asset.

ASM is the process you need to achieve asset reliability

Enter ASM, a process that integrates with work management, but with a very different objective. Whereas work management is all about the efficient execution of work, ASM is all about making sure you are executing the right work – all the time.

Many organizations have unsuccessfully tried to tackle ASM within their work management process. The reason this approach doesn’t deliver results is that ASM and work management have very different objectives and therefore require entirely different triggers, resources, data and technical solutions to be effective.

Beyond delivering optimal performance and management of risk on an ongoing basis, ASM also delivers benefits that are out-of-reach for many organizations:

- A consolidated, standard, component-based maintenance strategy – driving consistency of strategy but allowing for local operating context

- A consistent Master Data build for all plans and materials supporting execution

- Identification of undesirable risk

- Automatic detection of where to focus improvement initiatives

- Rapid deployment of relevant strategy changes across the entire asset base

Organizations typically see an immediate uplift in performance and reduction in costs on implementing ASM. The clarity generated from an ASM program can also improve work management, because the objective of the work management process become singular and clear, allowing the organization to do work more efficiently.

How does Asset Performance Management (APM) fit in?

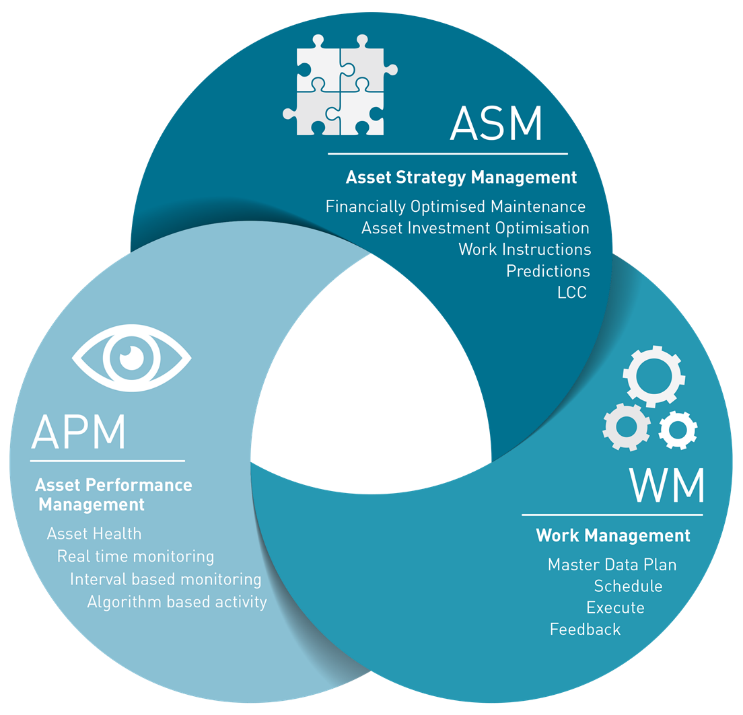

Some organizations may be familiar with APM, which is focused on maintaining asset health and condition. APM manages the ongoing performance of assets by monitoring current conditions or current performance data; and alerting the organization when an intervention is required to prevent an impending failure.

Types of monitoring range from a periodic assessment by a technician through to multi-parameter continuous monitoring devices. Essentially however, the intent is the same: understand the condition, determine if that condition is deteriorating and identify any impending failure so that rectification can be scheduled into the workflow. And, in doing so, avoid that failure.

Recently, the cost of technologies that support the online monitoring of asset operating parameters has fallen, leading to wider-scale adoption of online monitoring tools. APM, as a result, is getting cheaper and easier to perform. It’s good news for organizations – but it’s important to remember that these monitoring tools don’t take care of strategy.

ASM sits alongside APM to make sure that routine maintenance strategies and whole of life asset strategies are best-in-class and aligned to the performance requirements of the plant. It uses a consolidated base of Reliability Master Data that is deployed and connected across the entire asset base. Any updates to strategy follow a process to ensure that the change is effective (data-driven where applicable); and work-flowed to ensure review, approval and implementation. This may result, where applicable, in a single site-based change, driving the update of the corporate Reliability Master Data, and the resulting change is deployed automatically across an entire asset base.

ASM can also help to identify where it is cost-effective and practical to implement monitoring or APM. Hence, along with work management, you have a closed loop for reliability maintenance.

So, where do you start?

Most organizations will already have a work management process in place. Ideally, this process has been refined to ensure that assets are maintained and repaired quickly to minimize downtime.

But if you’re serious about asset maintenance then your next step is to implement an ASM plan. It’s the most effective way to deliver improvements, reduce costs and improve your existing work management processes.

Why? Because any reliability process must start with a strategy aligned to your performance goals. This strategy must be best-in-class and continually managed – it can’t be changed ad-hoc, without review and approval. By the same token, if effective local strategy changes are made, it is a waste not to electronically distribute that change to all relevant instances of that asset.

Implementing an ASM process puts the organization back in control of asset management; and will continually drive the execution of best-in-class strategies across the entire asset base.

Where does your organization sit on the Asset Strategy Management maturity scale?

Find out how you compare to best-in-class Reliability programs on this and other key measures with our short 12-question Asset Strategy Management Assessment and receive a custom report with our recommended path forward.